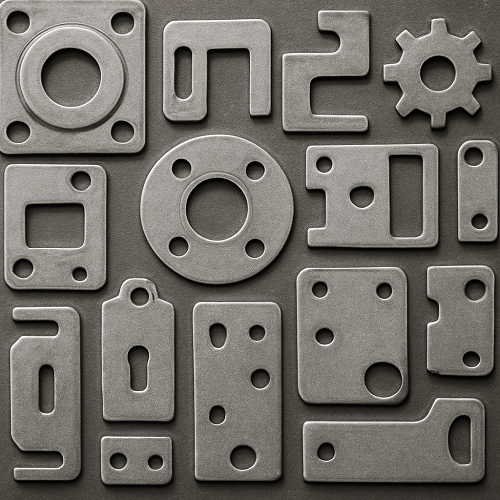

Stamped metal parts are essential components in modern manufacturing, serving as the backbone of countless mechanical assemblies and structural applications. Their primary function lies in transforming flat metal sheets into complex shapes with high accuracy and consistency. These parts can be designed to perform functions such as fastening, supporting, guiding, and enclosing within machinery, electronics, vehicles, and consumer products. Whether used as brackets, clips, housings, connectors, or decorative trims, stamped metal parts ensure structural integrity, functionality, and reliability. Their versatility allows manufacturers to achieve cost-effective mass production while maintaining tight tolerances and uniformity across all pieces.

Stamped metal parts are valued for their durability, precision, and adaptability. Produced using advanced stamping technology, they can be manufactured in a wide range of shapes, sizes, and thicknesses, tailored to meet specific project requirements. Features such as corrosion resistance, surface smoothness, and high tensile strength make them suitable for both heavy-duty applications and fine-detail components. Stamped parts can also undergo secondary treatments such as plating, painting, anodizing, or heat treatment, enhancing performance and longevity. Another key feature is scalability—once the die is designed, millions of parts can be produced with consistent quality, making stamping a highly efficient solution.

Stamped metal parts are available in various materials including stainless steel, aluminum, copper, brass, and carbon steel, each selected based on the application’s mechanical and environmental demands. Thickness can range from ultra-thin foils of 0.1 mm to heavy-gauge sheets exceeding 10 mm, depending on strength requirements. Dimensions are customizable, and tolerance levels can be maintained within microns using high-precision stamping equipment. Parts can be flat, formed, drawn, or embossed, depending on the design. Surface finishes can include brushed, polished, powder-coated, or plated options to meet both functional and aesthetic needs.

When using stamped metal parts, it is essential to follow proper design and handling practices. Designers should specify material type, thickness, and required finishes in advance to ensure the parts meet performance expectations. During assembly, stamped parts should be matched with compatible components to prevent stress or deformation. In cases where corrosion resistance is critical, users are advised to choose treated or coated surfaces. For industries requiring high-volume production, stamped metal parts can be integrated seamlessly into automated assembly lines, further reducing production costs and increasing efficiency. Proper storage in dry, controlled environments will maintain the integrity of the materials before use.

Stamped metal parts are indispensable across a wide range of industries. In the automotive industry, they are used in chassis components, engine brackets, and interior trims. The electronics sector relies on stamped connectors, terminals, and shielding elements. In aerospace and defense, stamped parts are critical for lightweight yet strong structural elements. The construction industry uses them in hardware, fasteners, and support systems, while appliance manufacturers utilize stamped parts in housings, panels, and fittings. Even in medical devices, precision-stamped components ensure safety and reliability in surgical instruments and equipment. Their ability to meet diverse industry standards makes them a universal solution for manufacturers worldwide.

The customer base for stamped metal parts is extensive, ranging from large-scale manufacturers to small and medium-sized enterprises. Automotive OEMs and Tier 1 suppliers benefit from their scalability and durability. Electronics manufacturers seek them for miniaturized, high-precision components. Construction and hardware companies value their strength and adaptability, while aerospace firms prioritize lightweight yet reliable parts. Appliance makers, consumer goods producers, and medical equipment manufacturers also represent significant customer groups. Engineering firms, product designers, and custom fabrication workshops rely on stamped parts for prototyping and tailored solutions.